Manhole Covers: Lifeline to Urban Infrastructure

These manhole covers don’t seem to be a so much more important component of the urban space but very indispensable element of our cities without which, our cities cannot breathe. They are so ubiquitous that one may find them at various places on streets and sidewalks keeping the access points for underground utilities hidden while being safe for people and moving objects. We will think about how important manhole covers are, types, materials, and the reasons that they are indispensable for modern cities in this blog.

What Are Manhole Covers?

Manhole covers are round or square plates used to cover any underground-opening. Utility chamber openings including sewer systems, electrical conduits, and lines for telecommunication are covered by manhole covers. Manhole covers serve two functions simultaneously: allowing people who have a legitimate access to underground systems are allowed but preventing a member of the public from falling into those openings. If manhole covers did not exist, it would greatly make work with urban infrastructure much more complicated, above all, much more dangerous.

Importance of Manhole Covers

Manhole covers are much more than face value. There are several reasons to make this special constituent so significant. Here are some:

Public Safety Manhole cover is basically the way of accident prevention. It literally means a dangerous exposure toward pedestrians and cyclists walking along a road at a very high speed. An accurately bolted manhole cover prevents any individual from falling into a manhole by mistake.

Access for Maintenance Utility workers gain access to the underground systems through manhole covers to rectify and inspect. Manhole covers allow city infrastructure to be suitably serviced.

Durability and Longevity: Manhole covers are made of robust materials like cast iron, steel, or composite materials, resistant to heavy loads from passing vehicles and other adverse weather conditions. They last for many decades with little or no maintenance.

Protections against Intruding Debris: Manhole covers cover debris, soil, and other foreign particles that are penetrating underground systems that cause obstructions or damages.

Types of Manhole Covers

Manhole covers are of different types for specific purposes and locations where they are installed. Among the best known are these types:

Solid Top Covers. Their tops are solid, seal entrance completely, and are for areas where entry is a rare occurrence.

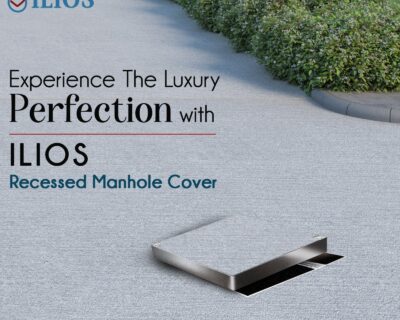

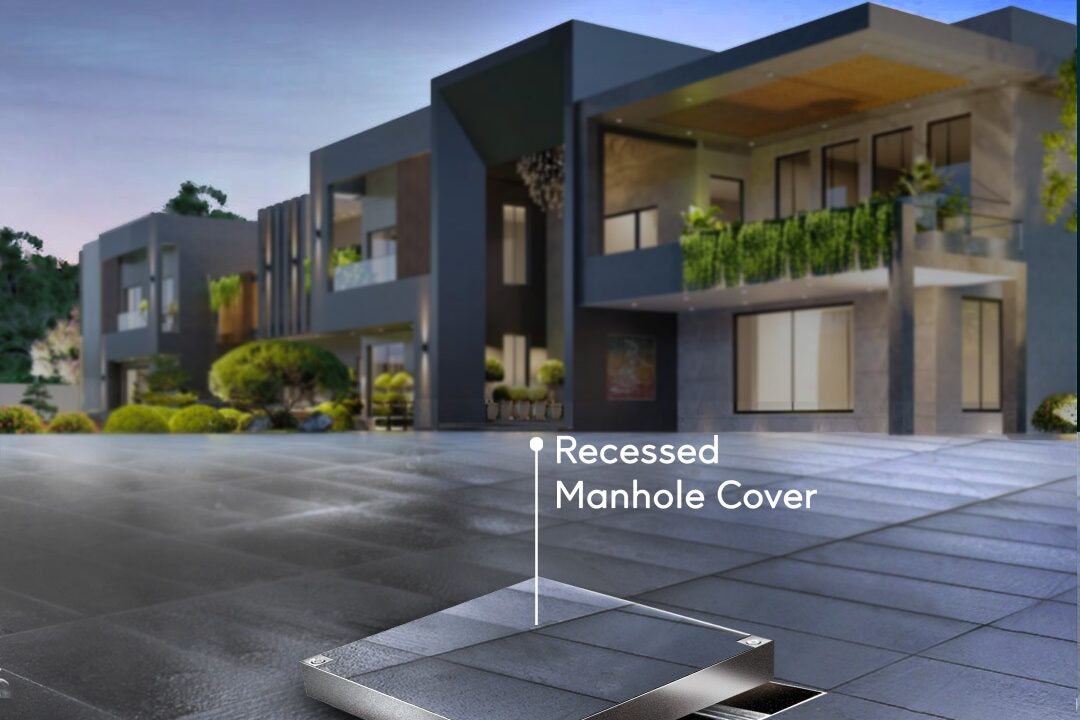

These covers are designed in such a manner that they blend with the background of the region. They can be given the same material of the surrounding pavement so that these can look less conspicuous.

The covers are also designed in such a way that they permit the gases while coming out from the underground chambers if the region demands air circulation.

Locking Covers

These covers may be sold in areas of high security where an access lock would be positioned to regulate entry into the critical infrastructure.

Special Design Covers: Some manhole covers feature logos, designs, or other distinctive characteristics representing a city or utility company.

Composition of Manhole Covers

The sort of material for a manhole cover depends on the purpose, location, and budget. Listed below are some of the most frequent materials used:

Cast Iron: Manhole covers can be made from cast iron that is very strong and light in weight. They can bear heavy loads as well as drastic weather conditions.

Ductile Iron: It is the development of the cast iron with greater flexibility hence it does not crack.

Steel: The light-weighted manhole made from steel is of great strength. These are used where the load of traffic is less.

Composite Materials: Composite covers include those made of fiberglass or resin. They are light. They have corrosion resistance and are non-conductive. They are quite suitable for those areas with electrical hazards.

Concrete: Concrete covers, as compared to the metal or composite covers, are relatively weak but economical, thus applicable to low-traffic areas.

Issues Which Cities Face with Manhole Covers

Despite the manhole covers being essential, cities face several problems with them as discussed below:

Theft: Used cast iron manhole covers are easy prey for the thief and can be sold as scrap metal. It creates safety risks along with associated expense in replacement.

Damage: Manholes crack or loosen due to heavy traffic and sometimes weather conditions, and then they need to be repaired or replaced.

Noise Pollution: Loose manhole covers create noisy commotion by the driving wheels, which forms an urban nuisance.

Entry of Water: The water seepage inside the underground system through unsealed manhole covers causes flooding and damage.

Design of Manhole Covers Innovations

New designs for manhole covers have been introduced with an aim to counter some of the above ills:

Smart Covers: Smart manhole covers whose interiors have inbuilt sensors can monitor the underground systems and alert regarding the maintenance requirement or illegal entry.

Anti-Theft Designs: A novel locking mechanism and non-metallic material can work as a shield against theft.

Noise-dampening covers: Scientists teamed up with engineers to conceptualize the idea of rubber gaskets or any other kind of noise-dampening covers that may help in decreasing the noise pollution.

Light weight material: Composite material helps manhole covers made more portable during the time of their maintenance without compromising their rigidity.

Manhole Covers and Environment

Manhole covers advance environmental sustainability. They ensure that underground systems are kept free of debris and water, causes pollution, and that necessary infrastructures are damaged. Besides, the use of manhole covers made from recycled material reduces waste and utilization of natural resources.

Conclusion

Of course, glamourous urban infrastructure does not involve manhole covers, but without their contribution to public safety and accessibility towards underground systems with sustainable functionality of cities, no one would refer to a tale of woe. Quality of materials, innovative designs, and regular maintenance can maximize manhole cover performance to the minimum of problems.