How to Pick the Right Manhole Covers: A Complete Guide

Manhole covers might seem like simple, everyday objects that don’t require much thought. However, if you’re someone responsible for selecting or replacing manhole covers, you’ll quickly realize there’s more to it than meets the eye. Manhole covers come in different shapes, sizes, materials, and load capacities. Choosing the wrong type or neglecting to replace a damaged one can lead to costly repairs, safety risks, or even legal issues. This blog will guide you through the key factors to consider when selecting the right manhole covers to ensure safety, durability, and cost-efficiency.

Why Are Manhole Covers Important?

Manhole covers serve as protective lids for openings that lead to underground utilities like sewer systems, drainage pipes, and electrical or telecommunications lines. Without them, these access points would be exposed, posing serious safety hazards to pedestrians, vehicles, and infrastructure. A well-chosen manhole cover not only ensures safety but also enhances the lifespan of the infrastructure below it.

Common Materials for Manhole Covers

One of the most important factors when selecting manhole covers is the material they are made from. Different materials offer various levels of durability, strength, and resistance to weathering and corrosion:

- Cast Iron

Cast iron has long been one of the most common and traditional materials used for manufacturing manhole covers. Known for its strength and longevity, cast iron covers can withstand heavy loads, making them ideal for high-traffic areas, such as roads and highways. They’re also resistant to corrosion, ensuring they last for many years. However, they tend to be quite heavy, which can make installation and maintenance a bit more challenging.

- Ductile Iron

Ductile iron is a modern alternative to cast iron. It offers similar strength but with added flexibility, which means it can absorb impact better without cracking. Like cast iron, it is commonly used in heavy-load areas. Its slightly lighter weight and enhanced durability make it a preferred choice in many industrial and commercial applications.

- Composite Materials

In recent years, manhole covers made from composite materials like fiberglass, resin, and plastic have become increasingly popular. These covers are significantly lighter than cast or ductile iron, making them easier to install and handle. They are also resistant to corrosion, rust, and theft (since they have no scrap value). Composite covers are ideal for areas with lower traffic, such as sidewalks, parks, and residential zones.

- Steel

Steel manhole covers are often used in applications where weight is a concern but strength is still required. They are typically lighter than iron covers but still offer good durability and load-bearing capacity. Galvanized steel covers, in particular, are resistant to rust and can be used in both outdoor and indoor environments.

- Concrete

Concrete manhole covers are typically used for low-traffic areas, as they are not as durable as iron or steel options. They are commonly seen in parks, sidewalks, and residential properties. While they are more affordable, they can crack under heavy pressure or extreme temperature changes, requiring more frequent replacements.

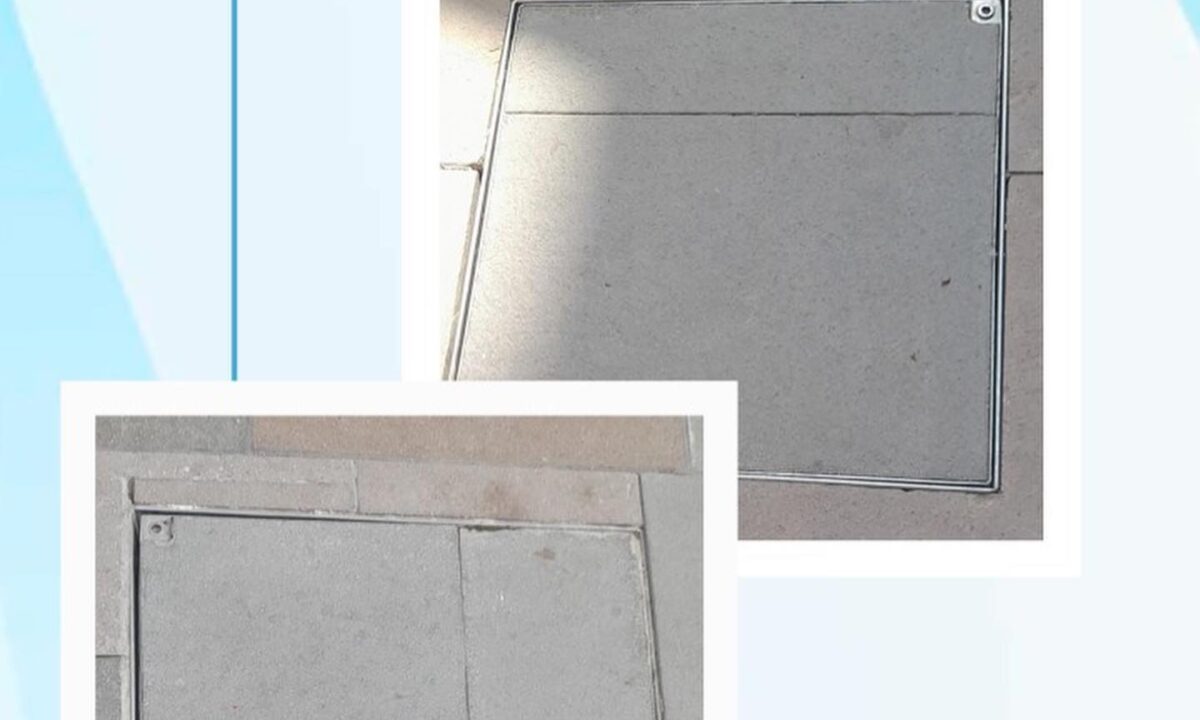

Size and Shape Considerations

Once you’ve decided on the material, the next step is determining the right size and shape of the manhole cover. These can vary depending on the location and purpose of the manhole.

- Round vs. Square

Most manhole covers are round because this shape prevents the cover from falling into the hole if it’s tilted. A round cover also distributes weight more evenly and is easier to move. However, square or rectangular covers are also common, especially in areas where the manhole is near curbs or edges.

- Standard Sizes

While sizes can vary, some standard diameters for manhole covers include 22, 24, and 36 inches. It’s crucial to measure the opening of the manhole accurately before selecting a cover to ensure a proper fit. A cover that is too small can be dangerous, while one that is too large may not sit properly.

- Custom Sizes

In some cases, a custom-sized manhole cover may be required, especially for older infrastructure or unique locations. Custom covers can be made in various shapes and sizes, but this will typically increase the cost.

Load Capacity: A Critical Factor

Another essential consideration when selecting manhole covers is load capacity, which refers to the amount of weight the cover can safely support. Manhole covers are usually classified into different load categories based on where they will be installed.

A15: Suitable for areas where only pedestrians will pass, such as parks and footpaths.

B125: Designed for light vehicles and pedestrian use, typically installed in residential driveways or parking lots.

C250: Often used on roadsides, in areas with moderate traffic.

D400: Ideal for main roads, highways, and industrial areas where heavy vehicles like trucks regularly pass.

E600 & F900: These are high-load-bearing covers used in areas like airports, docks, and heavy industrial zones where extremely heavy loads are expected.

Choosing the correct load rating is critical to ensuring safety and avoiding premature damage to the manhole cover.

Anti-Theft and Safety Features

In some areas, theft of manhole covers is a concern, especially with those made of materials like iron, which can be sold as scrap metal. To combat this, composite materials are increasingly being used, as they hold no resale value. In addition, many manufacturers now offer locking mechanisms or bolt-down systems to deter theft and unauthorized access.

Safety is another key consideration. Slip-resistant surfaces can help prevent accidents, especially in wet or icy conditions. Reflective markings or embedded LED lights can also be added to enhance visibility in low-light environments, making manhole covers safer for pedestrians and drivers alike.

Conclusion: Making the Right Choice

Selecting the right manhole covers is not as simple as it may first appear. It requires consideration of various factors, including the material, size, shape, load capacity, and specific safety features. A poorly chosen or damaged manhole cover can lead to safety hazards, costly repairs, and potential legal liabilities.